The Mixed Blanket Method for Bentonite Pond Sealant

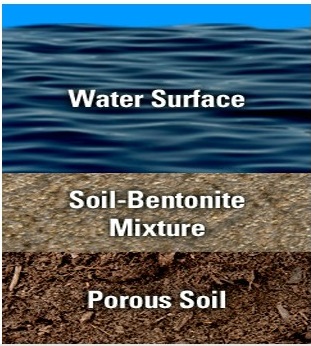

The Mixed Blanket Method of applying pond sealant is similar to the blanket method. Begin by preparing the surface to be sealed. Remove all rocks, trash, and vegetation, including trees and roots. Roots left in the ground will decay over time, which leaves the potential for future leakage problems. The soil level in the area to be treated is important. Investigate it before applying the bentonite. The moisture level should be optimum for good compaction. If the area is too wet, postpone sealing until moisture conditions are satisfactory. If it is too dry, add water by sprinkling. Fill all deep holes or crevices with a uniform mixture of 1 part bentonite to 5 parts soil, and cover and compact areas of exposed gravel with suitable fill material. Plow, disc or till the bottom of the pond 4″ – 12″ deep, then roll or drag the surface until it is smooth. This initial plowing and blending of the soil will assure consistency of the soil throughout the bottom of the pond before the bentonite is mixed into it. When this is complete, apply the prescribed amount of sodium bentonite. We recommend Pond Sealer, a mixture of powder and granular sodium bentonite for this application.

The bentonite can be spread by several different methods, however, we recommend a fertilizer or seed spreader to ensure even spreading. Mix the bentonite with the top 4″ – 6″ of soil by discing, tilling, or by hand raking. It is extremely important for the bentonite to be mixed uniformly with the soil. To ensure that no bare or thin spots will be left, we recommend multiple passes over the area. If livestock will have access to the pond, the cover coat must be thicker than 4 inches.

Finally, compact the pond bottom by rolling or tamping. Use care when filling the pond. A gentle water flow is recommended to prevent erosion of the soil/bentonite layer during this final phase. It may take several days for the bentonite to reach the point of full saturation and fill the voids in the soil. If a considerable amount of time elapses between applying the bentonite and filling the pond, it may be necessary to protect the treated area against drying and cracking. A mulch of straw or hay pinned to the surface by the final passes of the sheep foot roller gives this protection. Use rock riprap or other suitable material to protect areas where water inflow into the treated area is concentrated.

To learn more about our products and to place your order, contact us by phone at 405-382-1973 or complete our online contact form.